Our projects

APPLICATIONS

- Sealed Units

- Ramps

- Bus Shelters

- Partitions

- Backsplashes

- Counter tops

- Signage

- Marker board

- Furniture

- Art Installation

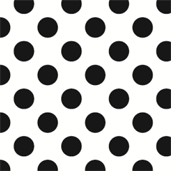

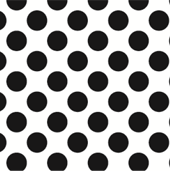

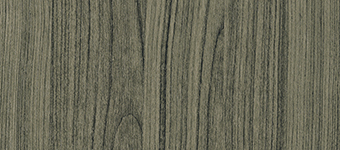

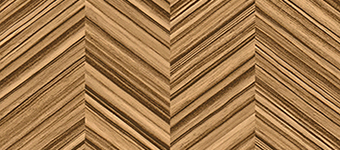

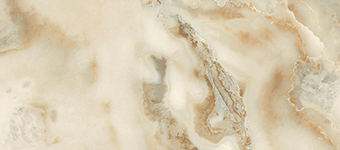

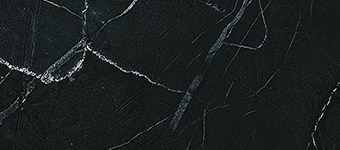

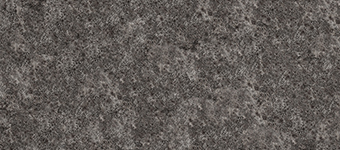

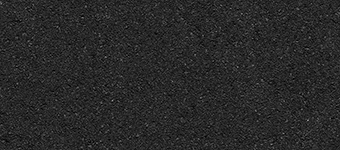

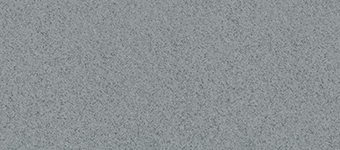

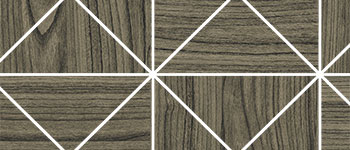

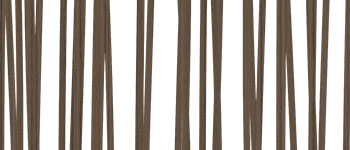

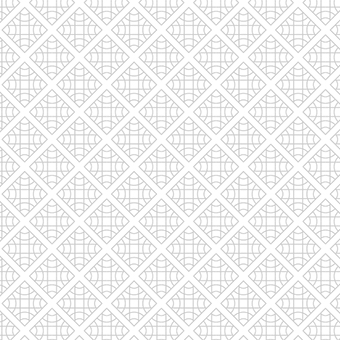

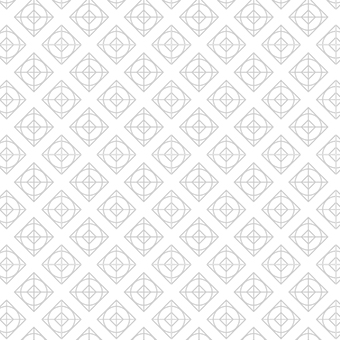

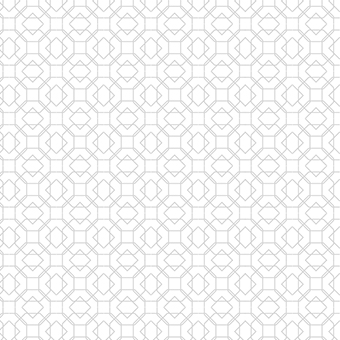

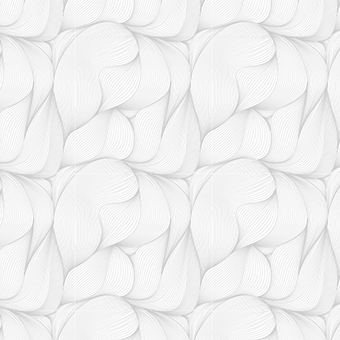

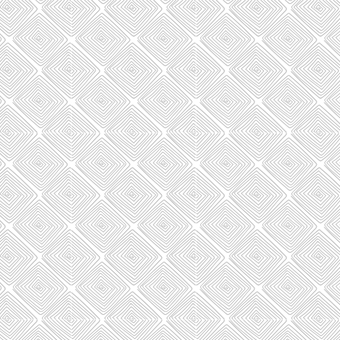

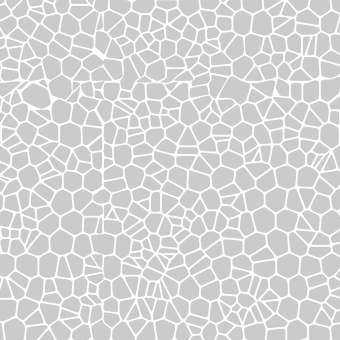

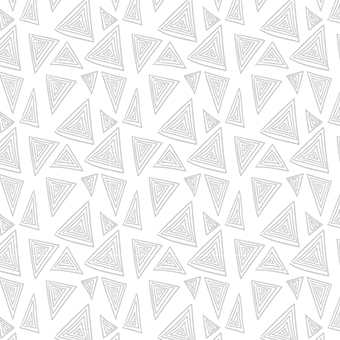

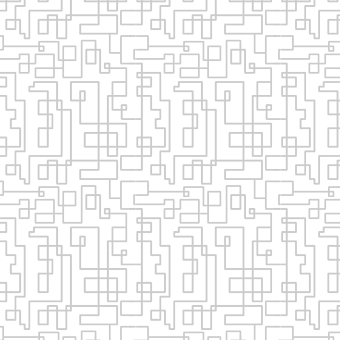

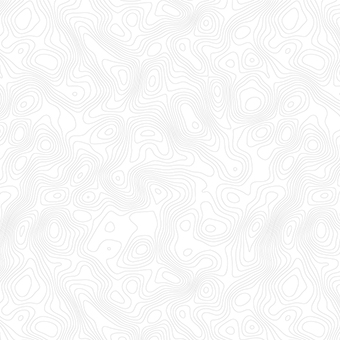

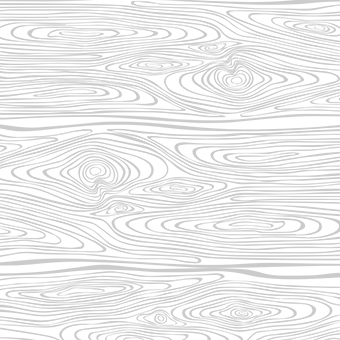

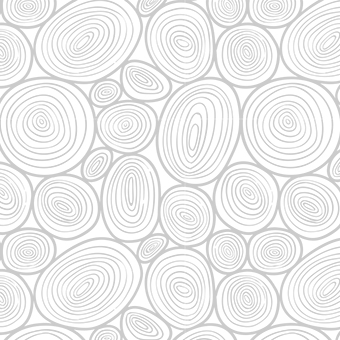

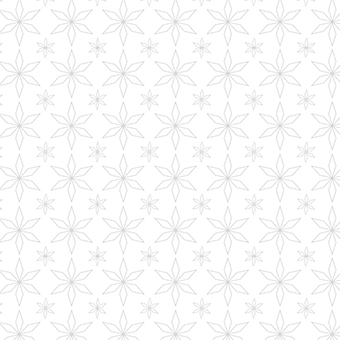

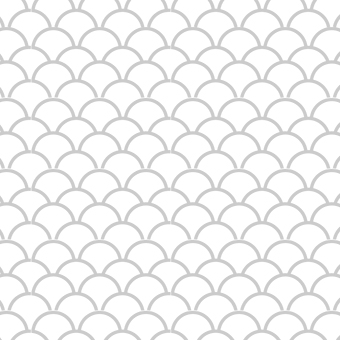

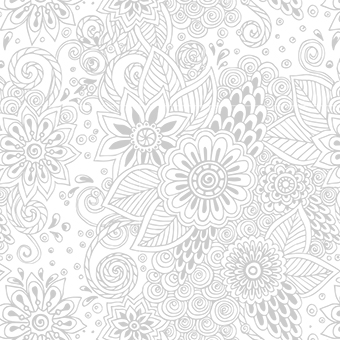

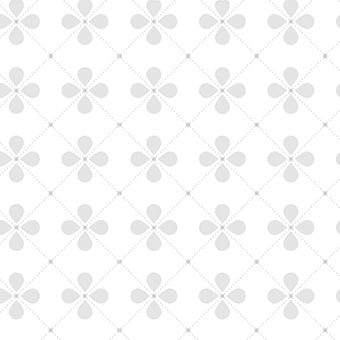

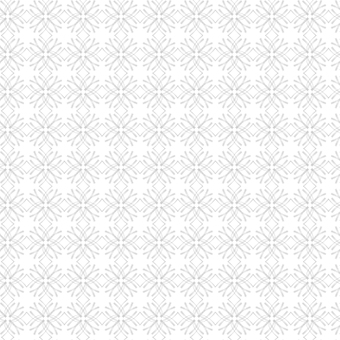

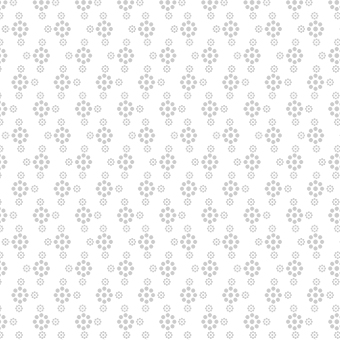

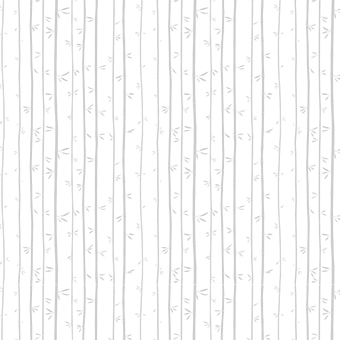

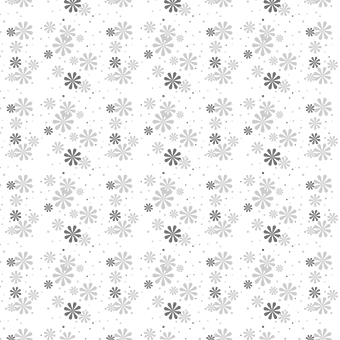

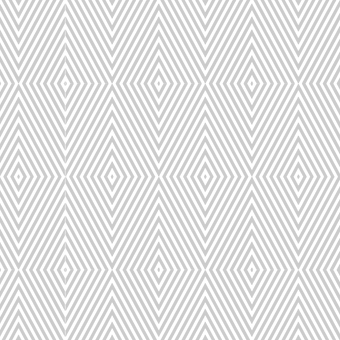

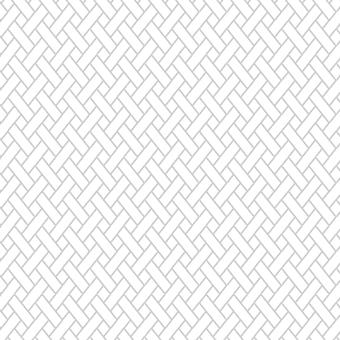

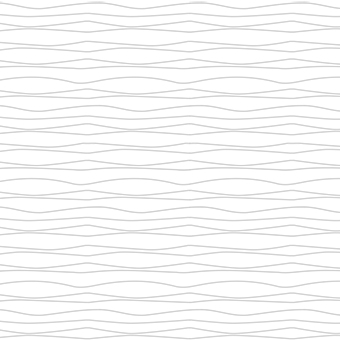

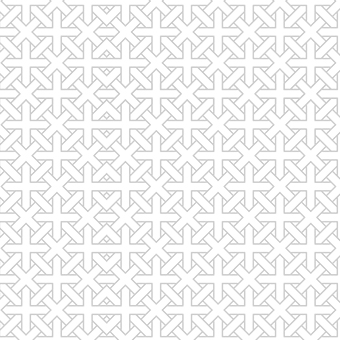

STANDARD PATTERNS

Here is a choice of digital print standard patterns offered. More patterns are also available.

White Wash Oak

Chocolat Oak

Mr Oak

Concrete Oak

Natural Oak

Dark Oak

Washed White Wood

Swedish Oak

Woody Allen

Zebrano Mocachino

Zebrano Chocolate

Zebrano Espresso

Zebrano Macchiato

Zebrano Zig

The Gold Rush

Deep Ocean

Green Lake

City Lights

Calacatta

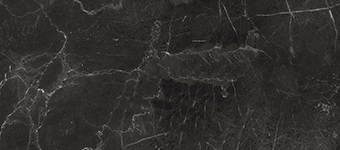

Dark & White

Carmen

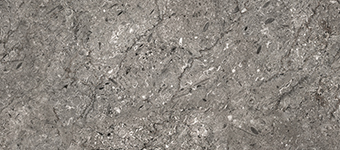

Alberta Rock

Spanish Wall

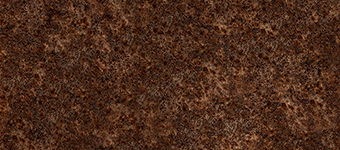

Ruggine Buio

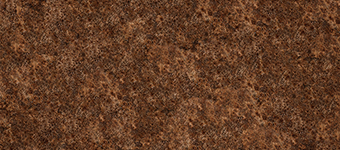

Ruggine Lumi

Ruggine Gregio

Lumi Asfalti

Nero Asfalti

Lab Stone

Side Stone

Silica Quartz

Pink Mammoth

Forest Drops

White Bishop

Bright Strip Oak

Oak Triangle

Grey Wood Triangle

Dark Strip Oak

Geodezic Dark

Geodezic Light

Geo Venga

Bamboo Horizon

The clown Chess

The Knight Chess

Modern Times

Arabian Nights

Eyes Wide Shut

Arabian Trio

Arabesque Brown

Arabesque Light Brown

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

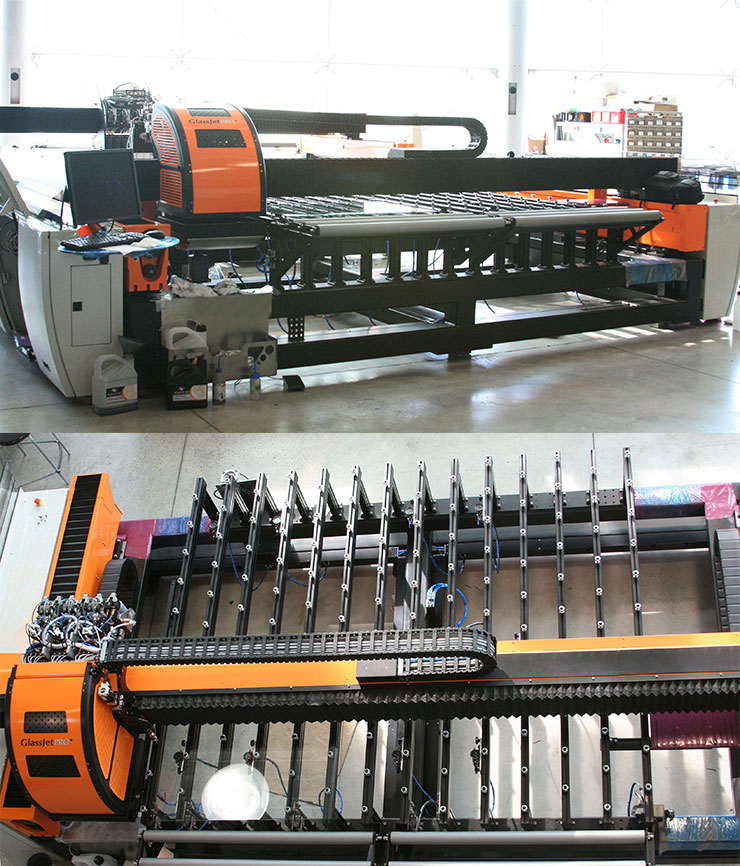

GLASSJET PRO PRINTER